Kondensataufbereiter ÖWAMAT 14 mit Vorabscheider

Kondensataufbereiter ÖWAMAT 14 mit Vorabscheider

Kondensataufbereiter ÖWAMAT 14 mit Vorabscheider

Svars:

18.5 kg

Pieejamība:

Uz pasūtījuma

Zīmols:

ELMAG

Preces kods:

DT1327676700 1 675,85 €

Ar PVN /

Product Highlights

You will find more details about ÖWAMAT condensate conditioners here: ÖWAMAT condensate conditionersTechnical Facts

- ÖWAMAT oil-water separators do not incur any energy costs, have a very long filter life and therefore very low-waste cartridge disposal.

Substitute

This article could be an alternative for you:Specifications

screw compressor delivery VCL-OIL

11.3 m3/min

piston compressor delivery VDL/Synthetik

10.1 m3/min

container volume

61.3 l

Filling volume

46.3 l

condensate feed

3 x IT 1/2”, 1 x IT 1”

Length

41 mm

Width

60 mm

Height

87 mm

Weight

18.5 kg

Sustainability with savings potential

From process plant control to pneumatic testing and control procedures - compressed air is indispensable in many parts of production. In their production, however, contaminated condensate is created. It contains, for example, hydrocarbons, dust and particles of dirt from the intake air, coolant and lubricant from the compressor and oil residues, rust, abrasion or sealant residues.Disposal as a cost factor:

Under the German Water Act, condensate must not be discharged into the sewage system as oily. This means that the condensate must either be disposed of professionally or processed on site. Disposal via external service providers is an expensive process. In addition to the disposal costs, internal investments such as approved collection tanks and monitoring equipment are required.There is a viable alternative: ÖWAMAT ensures oil-free waste water

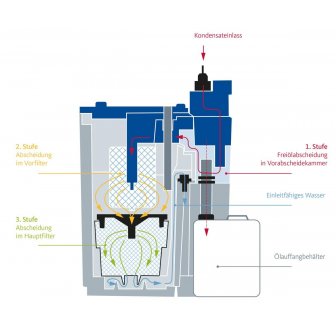

Condensate treated with ÖWAMAT can be discharged as purified water directly into the sewage system. The devices have building control approval and do not require a water permit.During treatment, the oil-containing condensate first enters the pressure load chamber (1) under pressure. There the pressure is reduced without causing turbulence in the subsequent separation tank for free oil separation (2). Coarse dirt particles that are carried along are caught in a removable trap (2). In the separation tank, the oil settles on the surface through shear force separation and is led into the oil collection container (4) which is protected against overflow.The filter makes the difference:

the pre-cleaned condensate flows through the oleophilic prefilter (5), which has a large active filter area. Flowing through from the inside to outside, it binds the remaining oil droplets and also absorbs residual, floating oil in the filter chamber.At its heart is the OEKOSORB main filter with cartridge technology (6): the last oil particles are removed reliably here. All that remains is water, which may be discharged directly into the sewage system.