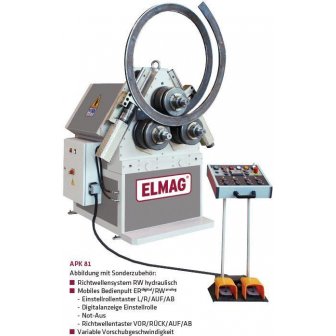

Hydraulische Ringbiegemaschine APK 81

Hydraulische Ringbiegemaschine APK 81

Hydraulische Ringbiegemaschine APK 81

Svars:

1600 kg

Pieejamība:

Uz pasūtījuma

Zīmols:

ELMAG

Preces kods:

DT1106562741 24 575,10 €

Ar PVN /

Product Highlights

You will find more details about Ring bending machines here: Ring bending machinesTechnical Facts

- Bending performance data for steel: 48,3x3,2 mm, Ø 400 min. / yield strength 240 N/mm2

- Drive motor 5,500 W

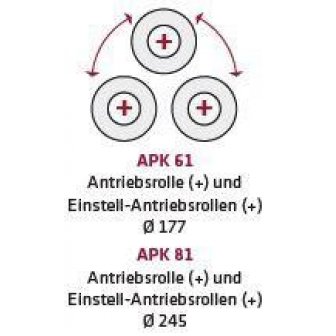

- Three drive rollers Ø 245

- Two hydraulic adjustment drive rollers

- Forward/backward feed 4,2 m/min

- Directional shaft adjustment mechanical

- High-quality planetary gear reducer

- Slip clutch as torque limiter

- Electrical and hydraulic overload protections

- Robust steel frame S355

- Mobile operator's desk ERdigital- Setting roller switch L/R/AUF/AB- Digital display Setting roller- Emergency stop

- Double foot pedal forward/backward thrust

Substitute

This article could be an alternative for you:Specifications

roll diameter above

245 mm

roll diameter below

245 mm

axis diameter above

80 mm

axis diameter below

80 mm

adjusting roll mechanical

- Num.

adjusting roll hydraulic

2 Num.

drive rollers

3 Num.

advance speed

4.2 m/min

positioning vertical

Yes

positioning horizontal

Yes

drive motor

5.5 W

hydro engine adjusting roll

1.5 W

hydro drive engine

- W

mains connection

400 / 50-60 V/Hz

Length

1.375 mm

Width

1.04 mm

Height

1.54 mm

Weight

1.6 kg

The

APK 81 ring bending machine is equipped with a 5,500 watt drive motor. Thanks to an efficient motor brake and an ideally proportioned reduction gear, they allow precise machining of medium and large profile cross-sections down to the last millimetre. Three drive rollers, including two hydraulically operated adjustment rollers, provide excellent power transmission for tight bend diameters.Top features

The standard features of the APK models largely enable single and small batch production of simple profiles. Special accessories for special applications are available on request.Design - High QualityAll

precision parts such as gear wheels, bending rollers, straightening shafts etc. are made of high-quality special steel (e.g. roller axles made of alloyed tempered steel 42 CrMo4, hardened and ground).Upgradable for series productionWith

a forward and reverse feed of 4.2 m/min, the APK drives provide outstanding performance characteristics. Simplehandling, quick adjustability, digital display and last but not leastthe robust machine design make the APK models ideal candidates for series production.Application examples -

Pipelineconstruction - Tankconstruction - Installers- Steelconstruction - Railingconstruction - Locksmiths- Forging- Mechanicalengineering - Sheetmetal work - Bodyconstruction - Car body workshopsStandard features

t - Standard castors - Hardenedspecial steel - Roller axles - Hardenedspecial steel - Straightening shafts - Hardenedspecial steel - Hydraulicbottom roller adjustment - Mechanicalstraightening shaft adjustment - Mobile control panel ER digital / Emergencystop - Double foot pedal forward/reverse- Operating instructions / CESpecial accessories

Round and tubularsteel bending rollers - Formsteel bending rollers - Angularsteel bending rollers - Angular bending device- Straightening shaft system RW hydraulic- Mobile control panel ER digital / RW analogue- Mobile control panel ER digital / RW digital- Spiralbending device - Position display/measuring device for profiles- 2 feedspeeds - Automatic lubrication- APK CNC control with display- Playback-Control (programming)