3D-Drucker XIONEER DESKTOP Twin-Head, Zweimaterialdrucker -inkl. XIONEER 3D Printer Software Maximale Druckfläche 295x295mm Maximale Druckhöhe 305mm Schichthöhe 0,15 - 0,35 einstellbar

3D-Drucker XIONEER DESKTOP Twin-Head, Zweimaterialdrucker -inkl. XIONEER 3D Printer Software Maximale Druckfläche 295x295mm Maximale Druckhöhe 305mm Schichthöhe 0,15 - 0,35 einstellbar

3D-Drucker XIONEER DESKTOP Twin-Head, Zweimaterialdrucker -inkl. XIONEER 3D Printer Software Maximale Druckfläche 295x295mm Maximale Druckhöhe 305mm Schichthöhe 0,15 - 0,35 einstellbar

Svars:

1 kg

Pieejamība:

Uz pasūtījuma

Zīmols:

ELMAG

Preces kods:

DT1868689894 22 469,70 €

Ar PVN /

Product Highlights

You will find more details about 3D printers here: 3D printersTechnical Facts

- Print head positioning: Core-XY process with 4 drives

- Closed installation space

- Access to the installation space: Polycarbonate sliding door

- Temperature control: Yes, approx. 40°C, with active cooling

- Two-material printing: Yes, with twin head technology

- Model material: PLA, PETG and others

- Support material: Break-away support material GeckoPeel

- Material: Material cassettes with int. memory

- User interface: 5' touch screen screen

- Main controller: ARM Cortex M3, Xioneer Nebula Board

- Built-in server: 1.5 GHz, 2 GB RAM, Linux-based

- Connections: LAN, WLAN (also as access point)

- Version: Xioneer Studio 0.90 / based on Repetier Host

- CAD file formats: .stl .amf .obj

- System requirements: Modern workstation with Windows 7 or higher

- Connections: WLAN, LAN (also as access point)

Specifications

max. print area

295x295 mm

max. print height

305 mm

adjustable layer height

0,15-0,35 mm

typ. extrusions web widht

0.45 mm

weight without material

46 kg

Professional 3D Printing. For real.

The fully automated office 3D printer impresses with its user-friendliness and productivity and is mainly used in prototype development and small series production. Thanks to patented technologies, the XIONEER DESKTOP meets the highest standards of quality, reliability and efficiency. The desktop offers users a high success rate with minimal waste. This is made possible by 6 patented technologies - and quality 'Made in Austria'. This quality becomes particularly clear with complex printing. The recipe for success includes the specially developed support material and innovative material application. 27 litre printing volume at 100% printing surface usage opens up new dimensions for 3D printing.Material: ModelPlus

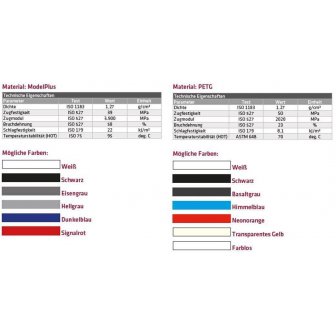

ModelPlus is an industrial-quality print material based on a modified formula of proven PLA print media. It has good mechanical properties very close to those of ABS but does not have the disadvantages of ABS such as distortion, delamination and odour development during printing. ModelPlus can be annealed at 110 °C to increase rigidity, which also increases the temperature stability to about 95 °C. Printing objects made of this material have a matt surface, which makes them ideal for presentation and demonstration purposes.Advantages:Mechanical properties similar to ABSmat Surface finishTemperature with temperature < 0,3 % Schwundresistance up to 95°C (after tempering)Application examples:Presentationmodels General prototype constructionGood alternative to ABSMaterial: PETG

Excellent all-round material, which stands out from many other 3D printing materials due to its high resistance and flexibility as well as its chemical and impact resistance. It is ideal for mechanical components, protective components and other objects subject to sudden orprolonged mechanical stress. The added glycol prevents embrittlement of the material at high temperatures. Thanks to its excellent chemical resistance, PETG is suitable for a wide range of applications, both in acidic and alkaline environmentsAdvantages:Robust, flexible and impactresistant Chemically resistant to acids and basesOdourless printingAvailable in transparentapplication examples:clamps, hinges, snap locksMechanical components for enduse Components for chemical processing