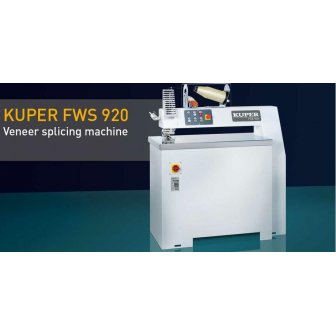

KUPER FWS 920 - Станок для сшивки шпона

KUPER FWS 920 - Станок для сшивки шпона

KUPER FWS 920 - Станок для сшивки шпона

Наличие:

Пред-заказ

Бренд:

KUPER

Код товара:

KUPER FWS 920 KUPER FWS 920 Veneer Splicing Machine

Does it all, takes little space and is cost saving: The compact KUPER FWS 920 features the same

technical advantages of the bigger KUPER FWS and provides the same efficiency – perfectly suiting craftsmen.

Small and economical.

The modern design of the KUPER FWS 920 is as convincing as the high feed speed for splicing

veneers. The special gluethread developed by KUPER is applied so precisely that tight joints and high tear-resistance are guaranteed. Even with very wavy veneers!

The standstill regulation reduces the temperature of the heater in standstill mode, so burning of the thread is avoided.

The KUPER FWS 920 of course is as simple to operate as all KUPER Zig-Zag Veneer Splicers.

Does it all, takes little space and is cost saving: The compact KUPER FWS 920 features the same

technical advantages of the bigger KUPER FWS and provides the same efficiency – perfectly suiting craftsmen.

Small and economical.

The modern design of the KUPER FWS 920 is as convincing as the high feed speed for splicing

veneers. The special gluethread developed by KUPER is applied so precisely that tight joints and high tear-resistance are guaranteed. Even with very wavy veneers!

The standstill regulation reduces the temperature of the heater in standstill mode, so burning of the thread is avoided.

The KUPER FWS 920 of course is as simple to operate as all KUPER Zig-Zag Veneer Splicers.

Advantages at a glance

- discs with tolerance compensating mechanism

- electrical heating system of industry machines

- standstill regulation

- electrical thread cutting roller

- automatic start by light sensor

- discs with tolerance compensating mechanism

- electrical heating system of industry machines

- standstill regulation

- electrical thread cutting roller

- automatic start by light sensor

openTechnical data KUPER FWS 920

Throat depth

920 mm

Feed speed

approx. 20 m/min.

Veneer thickness

ca. 0.4 – 2.0 mm

Operating voltage

400 V, 3 Ph, 50 cycl. or special voltage

Total connected load

approx. 0.97 kVA

Space requirement

(L x W x H)

1270 x 530 x 1480 mm

| Throat depth | 920 mm |

| Feed speed | approx. 20 m/min. |

| Veneer thickness | ca. 0.4 – 2.0 mm |

| Operating voltage | 400 V, 3 Ph, 50 cycl. or special voltage |

| Total connected load | approx. 0.97 kVA |

| Space requirement (L x W x H) |

1270 x 530 x 1480 mm |