Kundig Щеточные станки

In order to expand their range of applications by brushed and textured surfaces, more and more of our customers choose to add brush rollers to complement their sanders or even look for dedicated brushing machines. In serial production, brushing lines are already very common. Kündig builds such brushing machines but also provides solutions that add to the versatility of their wide belt sanders.Brushes and Brushing Machines

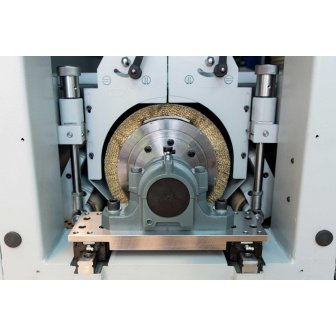

In the last years, precision requirements in textured wood surfaces have risen considerably. For example, parquet is rarely finished on site after installation, instead it needs to have tolerances of just tenths of millimetres from the factory in order to avoid height offset. Adjustment options comparable to a Kündig widebelt sander facilitate meeting these steep requirements. Units The add-on texturing brush unit is an upgrade to our widebelt sanders and a well proven solution for joineries or carpenter workshops that want to ad textured wood surfaces to their range of products. Integrated brushing units supplement our widebelt sanders and are located in the machine body. These brushes are mostly used by companies that do a lot of wood texturing and represent an uncompromising combination of sanding machine and brushing machine. They are available with or without oscillation as well as in different diameters and materials. We also build dedicated brushing solutions mostly for industrial purposes and often found in parquet production. These wood texturing machines are extremely heavy duty and very customisable. Sanding of cross grain sections is a very well known challenge known by almost all who process wood. With their disk brush unit, which is available as part of Kundigs range of widebelt sanders, the Swiss company found a reliable solution for cross grain sanding that perfectly eliminates scratches on cross grain areas of wooden workpieces such as kitchen doors. This is best achieved in combination with their patented oblique sanding technology. Another application of the disk brush unit, thanks to its specialized movement pattern, is rounding off work piece edges very consistently and evenly. Meaning that all of the workpieces edges will end up with the exact same radius. Furthermore, the disk brush unit can be used for intermediate filler or lacquer sanding on profiled and even workpieces. The disk brush unit is equipped with 24 rotating 5“ disks. The whole unit oscillates. Both the unit’s oscillation as well as the disc rotation can be steplessly adjusted in order to achieve the best possible surface finish.

As precise as a Widebelt Sander

Add-on Brush Unit

Integrated Brush Unit

Designated Brushing Machines

Disk Brush Unit - The Solution for Cross Grain Sanding

For our factory brush unit we offer a variety of brush types: Structuring Brushes equipped with different bristle types, Sanding brushes and Scotchbrite® brushes. Horsehair brushes for workpiece cleaning are also available. Sanding Disc with eccentric Oscillation Brushes for Sanding or Structuring

Carousel Brush Bk

Brush Roller Bs

Brush Roller Bst

Brush Roller Bsb

Carousel Unit

Sanding Brush

Structuring Brush Roller

Brush Roller with 3M Scotchbrite

Working Widths

650mm

1100mm

1350mm

1600mm

1900mm

2200mm

Other working widths on request