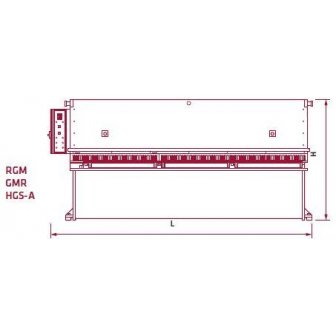

Mechanische Tafelblechschere Mod. GMR 2600x4 mm

Mechanische Tafelblechschere Mod. GMR 2600x4 mm

Mechanische Tafelblechschere Mod. GMR 2600x4 mm

Svars:

4000 kg

Availability:

Pre-order

Ražotājs:

ELMAG

Product SKU:

DT1042416372 43 076,00 €

incl. VAT /

Product Highlights

You will find more details about Mechanical sheet metal shears - GMR here: Mechanical sheet metal shears - GMRTechnical Facts

- High quality standards

- Robust, durable design

- High cutting accuracy

- Welded monoblocksteel construction with very good vibration damping

- S275 material with very high tensilestrength to absorb bending moment

- Durable cutting blades with two cutting edges, hardened special steel

- GMR 4 mm models: Cutting gap adjustment for quality cuttingof different material thicknesses and types

- NC-controlled backgauge with precise motor adjustmentand ball screw

- High adjustment speed 110 mm/s,adjustment range 600 or 800 mm

- Back gauge with automatic reset

- CE safety devices

- Integrated safety with kerf cover

- Back of machine with light barrier

- Emergency stop button on the machine and on the operating column

- Easy handling

- Support arm with ruler and side stops

- Support table with ball rollers

- Easily programmable NC ELGO P 9521 controller

- Two operating modes, manual and automatic

- Clear GMR control panel with control buttons

- Mobile operating column with foot switch for automatic mode

Specifications

Cut length

2.56 mm

cutting capacity 42 kg/mm²

4 mm

cutting capacity 70 kg/mm²

2.5 mm

kerf min. / max.

0.05 - 0.5 mm

Stroke rate

42 1/min

main drive engine power

7.5 kW

backgauge engine power

0.75 kW

backgauge adjustment

800 mm

adjusting speed

110 mm/s

Cutting angle

1.5 °

Desk length

2.19 mm

support arms

2 Num.

width without support arms

2.265 mm

transport width

1.83 mm

Overhang length

100 mm

Desk height

900 mm

oil tank volume

- l

Length

3.4 mm

Width

2.76 mm

Height

1.51 mm

Weight

4 kg

Super-cycle rateThe

GMR guillotine shears for 4.0 mm sheet thickness cycle at 42 strokes per minute. They are therefore a cost-effective solution for serial cutting. Their maximum cutting length is 2,560 mm.Cutting programmingThe

ELGO NC control offers a simple and fast cutting programming with a manually triggered, motorized positioning and automatic resetting of the backgauge.Very fast and accurateThe

backgauge is moved to the cutting dimension at 110 mm/s and positioned exactly. A precision drive with ball screw provides the accuracy required. Hit the sheet metal, press a button or get an impulse from the foot pedal - that's all.The

manual cutting gap adjustment of the GMR 4 models allows an optimization of the cutting quality depending on the sheet thickness and the material type.Top accessories

GMR model can be equipped with a pneumatic sheet holding device for exact positioning of thin sheet metal sections.TECH-INFO - Gap Adjustment TableThe

cutting quality of guillotine shears depends essentially on the correct adjustment of the guillotine gap. Even with thin sheets, a straight cut with low edge indentation can be achieved. Diagram: Optimum cutting gap adjustment as a function of sheet thickness.Standard features

Cutting knife with two cutting edges, special hardenedsteel - GMR 4 models: Cutting gapadjustment device - NC-controlled backgauge with ballscrew - CE safetydevice - Support arm with ruler and side stops- Support table with ballrollers - GMRcontrol console - NC control ELGO P 9521- Mobile operating column with foot release and emergencystop button - Operating instructions / CESpecial accessories

Angle stop with scale- Sheet metal holding device type I or type II- 1,000 mm Backgauge