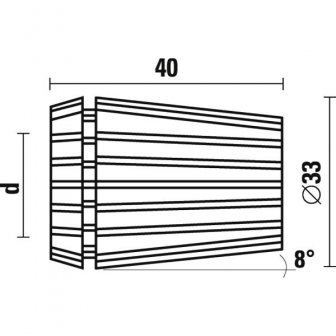

SPRING COLLETS ER 32 - DIN 6499 d=Ø 9,5 -

SPRING COLLETS ER 32 - DIN 6499 d=Ø 9,5 -

- Precision= 0,01 (0.0004" T.I.R.)

- CNC high precision spring collets for ER32 tool holders.

- They are built in spring steel and grounded both internally and externally for best accuracy and precision.

- Klein® high precision spring collets allow to reduce vibrations on tools and motors during routing operations, ensuring a longer life of the tool and electrospindles. Using these spring collets on our high quality tool holders will give you the very best tool performance.

NB: Replace collets every 500 to 600 hours of machine time or every 6 months if running 8 hours a day. Replacing the collets will ensure your operation runs consistency and prevents from tool breakage.

HOW TO SETUP COLLET AND NUT PROPERLY

HOW TO SETUP COLLET AND NUT PROPERLY

Right procedure to assemble the collet in the nut:

- place the collet diagonal to the clamping nut and lock it from the side by pressing it from top

- screw the nut in and be sure the shank is correctly inserted in the spring collet to avoid breakage

- tighten the nut using the apposite key in the proper demount device / tightening stand (see our item art. T139)

Do not place the spring collet in the collet chuck before you have it properly inserted in the nut.

Correct procedure for tool and spring collet changes:

- place the collet chuck in the proper demount device / tightening stand (see our item art. T139)

- loosen the clamping nut

- open the clamping nut and pull the cutting tool out holding it on the shank

- release the collet from the clamping nut by applying a lateral pressure

DID YOU KNOW? Collets are manufactured from spring steel and regular usage causes a loss of elasticity. Therefore, collets need to be replaced regularly as part of on-going maintenance while the average collet should be replaced every 500-600 hours of run time. Avoiding regular replacement can lead to brittle collets, which may crack or break, and cause permanent damage to the spindle. Replacement of collets is more economical than replacing router bits or expensive spindles. Rigidity and concentricity are the key elements in any routing application. Periodically, tool holders should be examined for wear and if necessary replaced to maintain great cutting performance. The simple process of colleting router tools, maintaining collets, and regularly replacing them - safeguards productivity and ensures a perfect finish.

Features and product variants

| Item | d |

|---|---|

| T119.020.N | Ø 2-1 |

| T119.030.N | Ø 3-2 |

| T119.032.N | Ø 3,2 - (1/8”) |

| T119.040.N | Ø 4-3 |

| T119.048.N | Ø 4,8 - (3/16”) |

| T119.050.N | Ø 5-4 |

| T119.060.N | Ø 6-5 |

| T119.064.N | Ø 6,4 - (1/4”) |

| T119.070.N | Ø 7-6 |

| T119.079.N | Ø 7,9 - (5/16”) |

| T119.080.N | Ø 8-7 |

| T119.090.N | Ø 9-8 |

| T119.095.N | Ø 9,5 - (3/8”) |

| T119.100.N | Ø 10 - 9 |

| T119.110.N | Ø 11 - 10 |

| T119.120.N | Ø 12 - 11 |

| T119.127.N | Ø 12,7 (1/2”) |

| T119.130.N | Ø 13 - 12 |

| T119.140.N | Ø 14 - 13 |

| T119.150.N | Ø 15 - 14 |

| T119.159.N | Ø 15,9 - (5/8”) |

| T119.160.N | Ø 16 - 15 |

| T119.170.N | Ø 17 - 16 |

| T119.180.N | Ø 18 - 17 |

| T119.190.N | Ø 19 - 18 |

| T119.191.N | Ø 19,1 - (3/4”) |

| T119.200.N | Ø 20 - 19 |