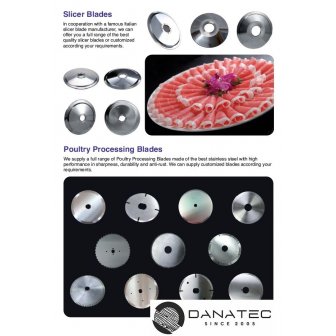

Circular knives

Application: intended for shortening and division.

Material: rubber, leather, corrugated board, insulation materials, plastic, non-ferrous metals, steel.

Machine: cutting machines and manufacturing centers.

Depending on the use of the disc knives leave to a hardness of 56 - 64 HRC. In standard production, circular knives are delivered without surface treatment; upon customer request, circular knives can be coated with PVD (for example, TIN, TICN or TIALN) or Teflon.

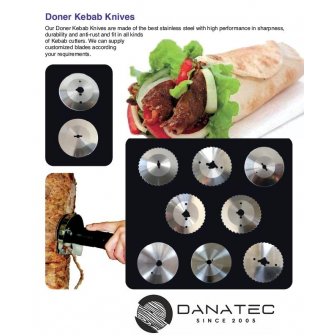

For use in the food industry (for example, for cutting canned vegetables or deep-frozen foods - fish, meat, etc.), circular knives are made of stainless steel, which meets hygiene requirements; for the food industry we supply, for example, cutter knives, knives for removing veins and films from meat, knives for meat grinders, minced meat mixers and other meat processing equipment, waste knives, knives for packaging machines, etc.

Given that circular knives are made only on request, the following data should always be indicated in requests and orders:

outer diameter of a circular knife;

thickness;

the diameter of the holes for the shaft of the circular knife;

diameter, quantity and pitch of the drive holes of the circular knife;

the type of material that should be used to produce the circular knife;

embodiment of a blade of a circular knife;

geometry of cutting a circular knife;

blade length of a circular knife;

type of material being cut.

HSS circular knives are not only used for cutting plastic. We also produce circular knives for cutting rubber, circular knives for leather, circular knives for cardboard, circular knives for cutting paper, circular knives for cutting foam and foam, circular knives for sheet metal, circular knives for dividing insulation materials, circular knives for cutting foil and films. The cutting edge of these tools is very diverse and depends on the type of material being cut. May have a single-sided blade, with grinding backing or double-sided blade, etc.